How To Grease A Floor Jack

So while regular bleeding may seem cumbersome it is absolutely necessary if you wish to keep your jack in working condition.

How to grease a floor jack. Using a floor jack that has air in its system is ill advised and extremely dangerous. Although your floor jack is a closed system it is still a good idea to replace the hydraulic oil on occasion. Failure to regularly bleed your jack is liable to result in its sudden failure and inability to support massive loads. Grease tends to attract a whole lot of dirt and since floor jacks are lubricated using grease you would expect them to be quite dirty.

Once you have finished using the floor jack make it a habit to wipe it down so as to. To grease u joints in your car properly follow the instructions below. Your floor jack is lubricated using grease due to the fact that grease is solid and does not spill like oil. Use a creeper or wood cardboard to slide under the car then locate the rear axle.

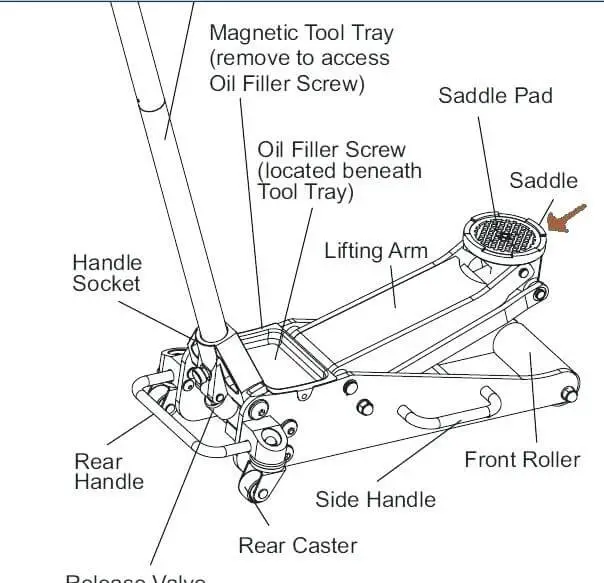

These important maintenance tips will help keep your jack working for ye. To add oil to a hydraulic floor jack start by making sure the jack is completely lowered by turning the jack s release valve counterclockwise until it s as low as it can get. Step by step how to bleed air add oil grease maintain your hydraulic floor jack. After lifting your car using a floor jack let it sit on the jack stands.

You will just need to use a piece of cloth to wipe it down immediately you finish using it. Unfortunately grease seems to attract a lot of dust and dirt and as such you should make it a habit to clean your jack. For smooth operation plan on changing the fluid once every couple years. Learn how to refill the hydraulic oil in your floor jack to keep it working properly.

The hydraulic oil is what will make the floor jack have the pressure and capacity to lift your loads without much difficulty. Some higher quality floor jacks will include a grease fitting for the hinge system but a majority of jacks do not.