How To Install Ceramic Spark Plug Boot

/stories/2018/08/100692.jpg)

Heat protection up to 600 deg.

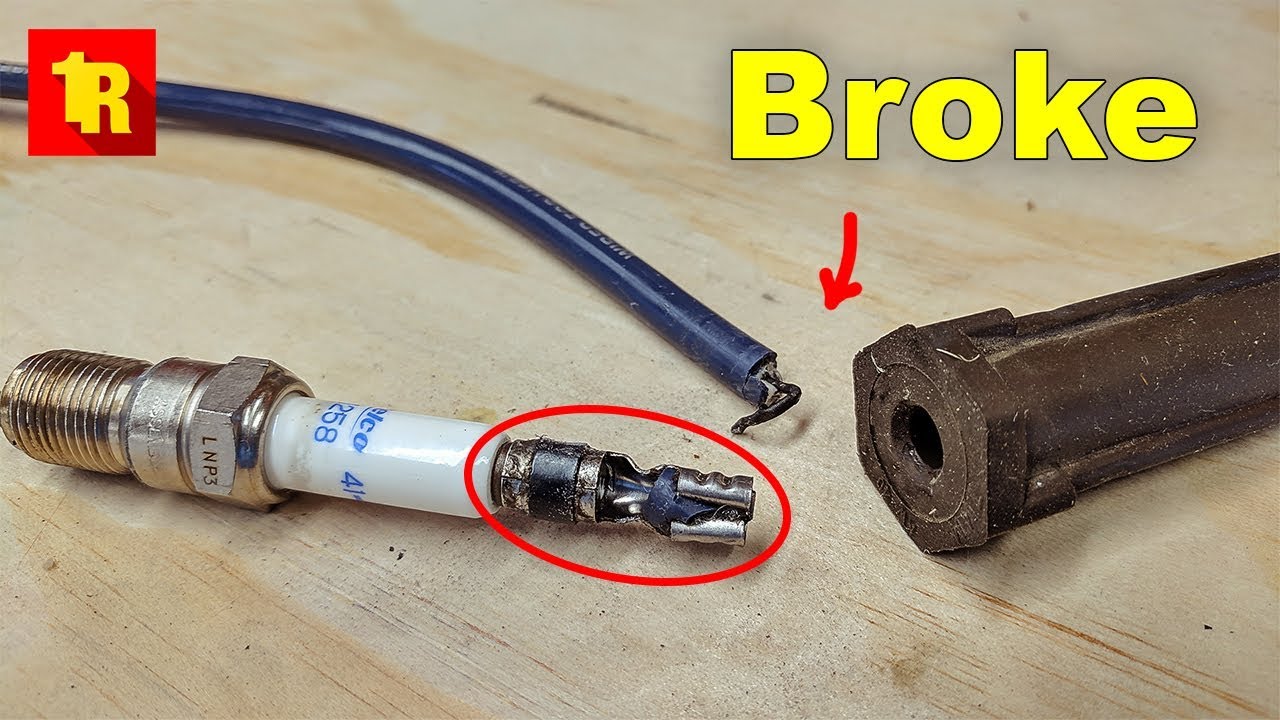

How to install ceramic spark plug boot. Thundervolt 8 2mm ignition wire set spiro wound universal fit 135 deg. Then push the boot over the exposed terminal of the new plug and press it firmly into place. If the cable appears cracked brittle or frayed or is saturated with oil have it replaced. Improperly installing the spark plug boot causes a weak spark which reduces the fuel efficiency of your vehicle.

6 examine the spark plug cable before attaching its boot to the plug. Only 40 ohms per foot resistance. We installed plug boots and terminal ends that are used for socket style distributor caps. Ceramic boot black part number.

Here is another video to help assemble a spark plug wire. Cut the spark plug wire to length with a pair of wire cutters. Do install a length of clean fuel hose or a new spark plug boot on the insulator so it can be properly handled during adjustment and installation. Hp boots spark plug boot protectors combine 304 stainless steel and ceramic insulation to reflect heat and provide a heat barrier for extreme conditions.

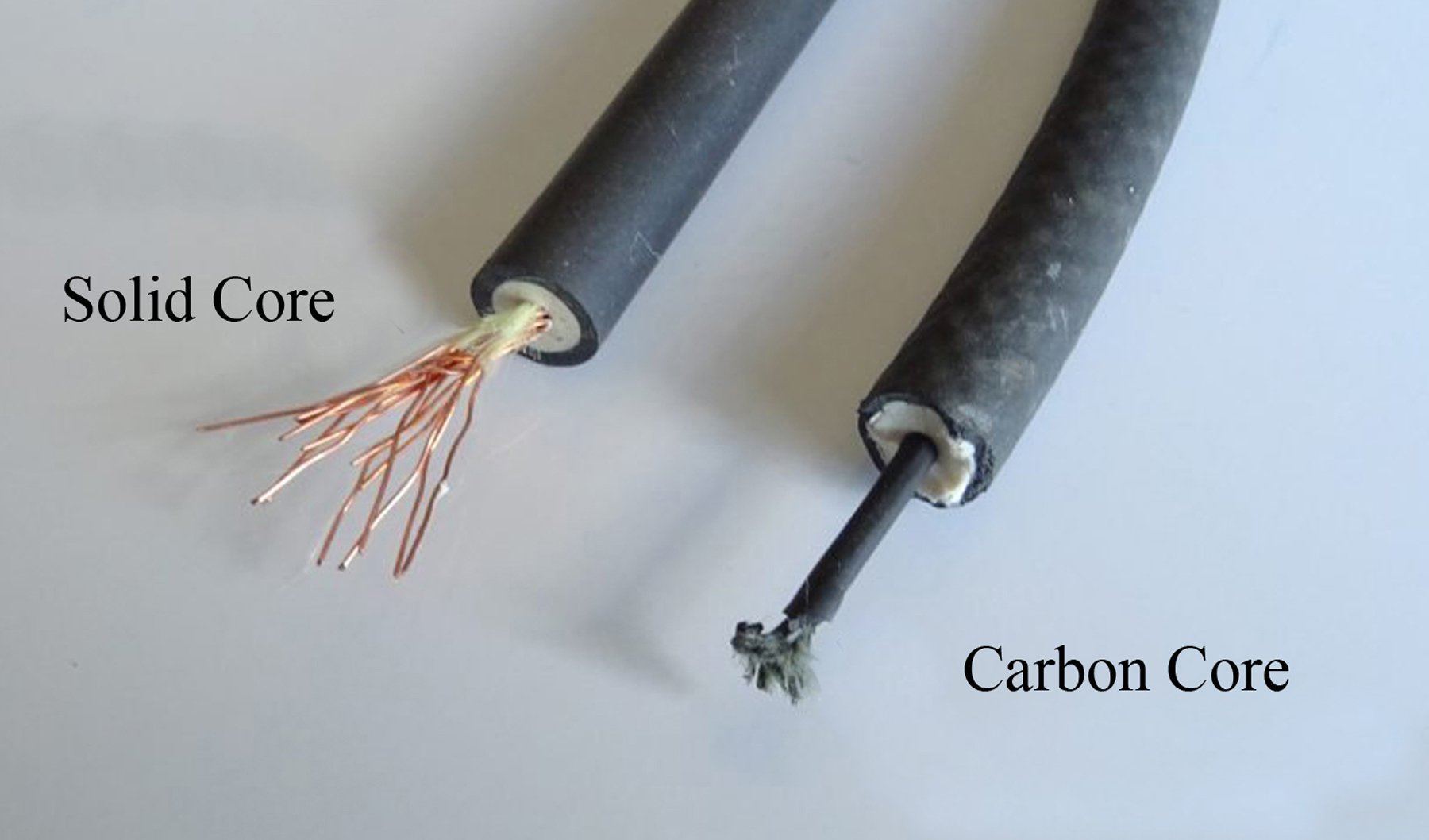

As a final note most spark plug manufacturers discourage using anti seize compounds on spark plug threads because metallic based compounds can spatter onto the insulator tip and cause a misfire. They are not very flexible so we make pre formed straight 90 degree and 135 degree configurations. Hp boots can withstand constant 1 800 degree temps and up to 2 200 degree. 100 percent silicone two layer jacket.

Push the wire until. Slide the cut end of the spark plug wire into the end of the stripping crimping tool supplied with the replacement spark plugs wires. Ferrite spiral wound coated core. It also shows where not to use the grease and the problems you might experience with.

This video show the proper us of dielectric grease on spark plug wires. Before you attach the boot to the spark plug apply some silicone lubricant to the inside of the boot.

%2C445%2C291%2C400%2C400%2Carial%2C12%2C4%2C0%2C0%2C5_SCLZZZZZZZ_.jpg)