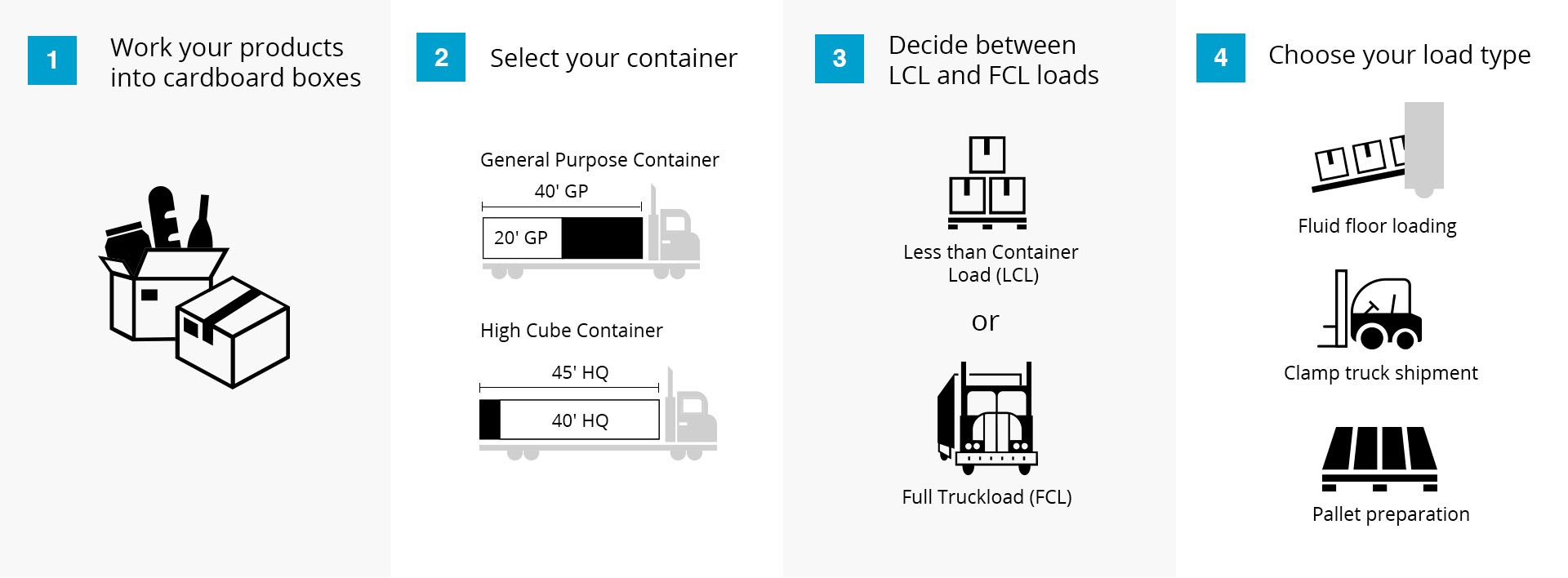

How To Load Floor Loaded Shipments

The basics truckload shipping refers to the hauling of freight over the road by filled to capacity tractor trailers.

How to load floor loaded shipments. There are two loading strategies. Floor loaded shipments require load bars and straps to be strategically placed throughout the load to prevent it from shifting. The floor of the container is made of wood. Machine weight 15 lb ft2 x 0 5 svc clear 10 lb ft2 x total area total area the floor loading should not exceed 240 kg m2 50 lb ft2 with a partition allowance of 100 kg m2 20 lb ft2 for a total floor load rating of 340 kg m2 70 lb ft2.

Tractors are the front part of a truck with the engine and driver and maybe a bed and trailers are usually a fully loaded 48 or 53 long trailer the cargo is either floor loaded or palletized. All shipments should be properly secured using load bars straps. How to properly floor load a container. If there s wall board covered ceiling suspended from the underside of that floor the dead load increases to about 10 pounds per square foot.

As a verb load is to put a load on or in a means of conveyance or a place of storage. A weight to be carried while shipment is a load of goods that is transported by any method not just by ship. If the floor of the. Feel free to make your own wooden braces to secure items within the container.

Floor load the container keeping everything low to the ground. It is the shipper s and the carrier s responsibility to ensure that shipments are loaded into a trailer in a manner that prevents the load from shifting during transit. Floor loading formula floor loading is. A typical wood frame floor covered with carpet or vinyl flooring has a dead load of about 8 pounds per square foot.

The dead load on a floor is determined by the materials used in the floor s construction.