How To Machine Glass Mica Ceramic

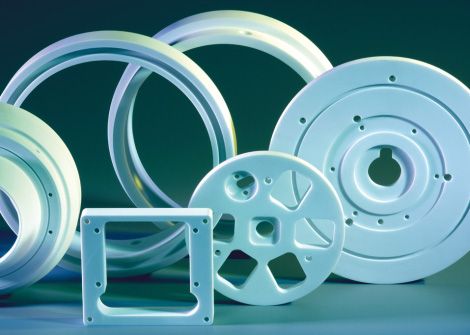

Machine complicated shapes and precision parts from these glass mica ceramic bars in a fraction of the time it would take using other types of fired ceramic.

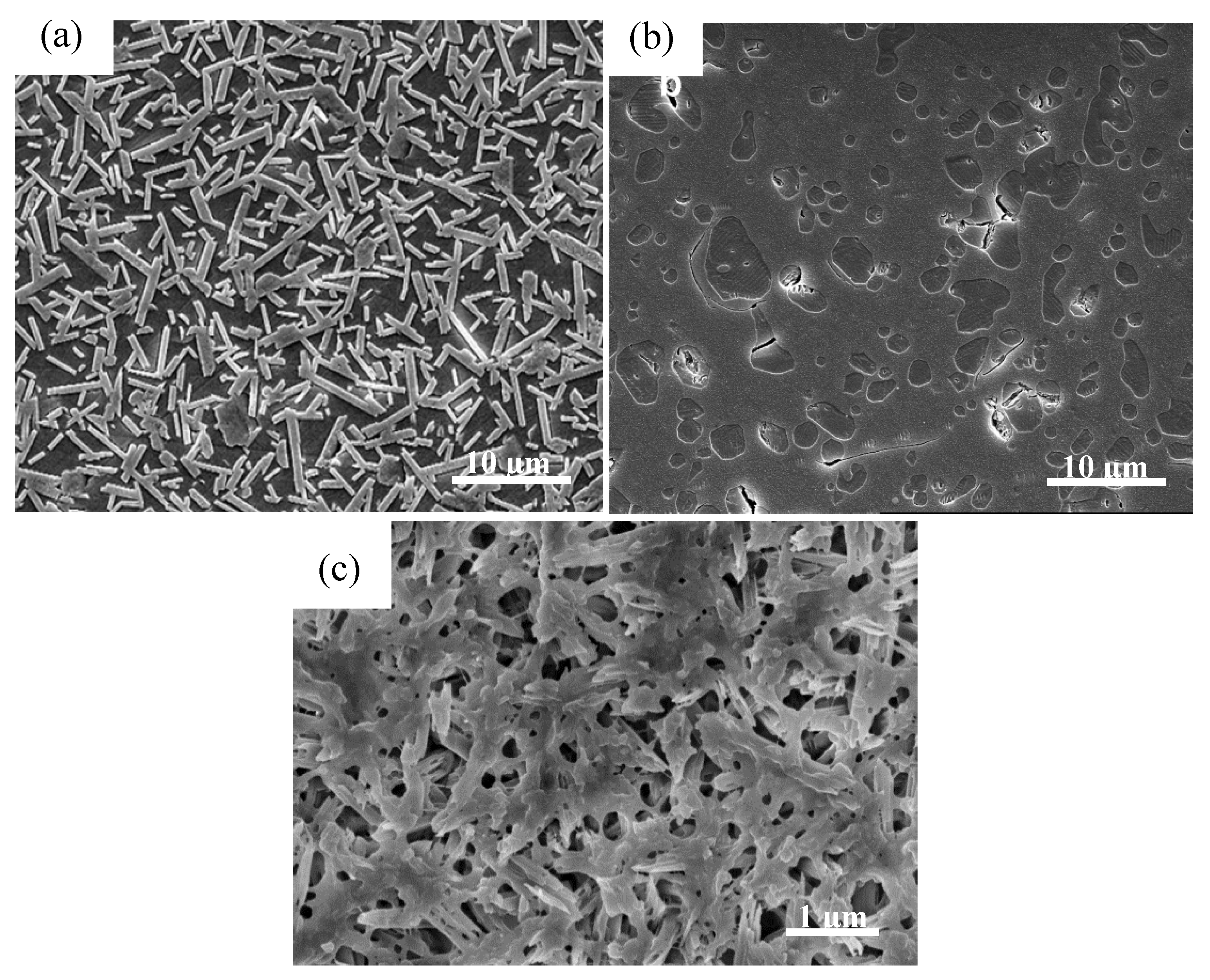

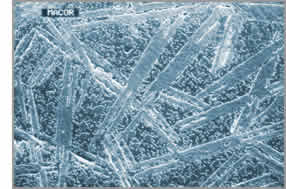

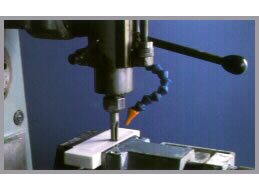

How to machine glass mica ceramic. For technical drawings and 3 d models click on a part number. Cut down into the work. Wheel cutting is the most satisfactory method of cutting glass mica composites. Cut across the grain whenever possible.

Macor machinable glass ceramic can be machined with high speed steel tools but carbide tools are recommended for longer wear. Machine complicated shapes and precision parts from this glass mica ceramic in a fraction of the time it would take using other types of fired ceramic. Corning is well know for its glass products and macor is a hybrid machinable glass ceramic that can be fabricated into intricate shapes with tolerances on the order of 0 0002 in with ordinary carbide tooling. A thinned web drill will reduce cutting forces and allow increased feedrates.

Work slowly and steadily do not force the tools and keep tool speed to suggested levels. Achieve the best results by using a water soluble coolant such as cimstar 40 pink especially formulated for cutting and grinding glass or ceramics. Machine wet with flood coolant or machine dry. Drills smaller than 1 5mm 062 should be machined dry.

If available bonded diamond wheels are preferred. Use a bonded silicon carbide type abrasive cut off wheel. Holes as small as 1mm 004 can be machined. Macor machinable glass ceramic has the versatility of a high performance polymer the machinability of a metal and the performance of an advanced technical ceramic.

For the low to medium volume precision work macor is a material that even a modestly equipped shop can machine into precision ceramic parts. Carbide c2 drills are recommended for extended tool life. It is a hybrid glass ceramic and offers a unique combination of properties from both families of materials. Also known as mykroy mycalex.

.jpg)